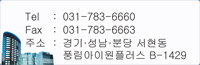

* Dimensions in Millimeters

|

| |

| |

Mechanical | |

| Mechanical Life | 50,000 cycles |

| Durability of Inlay | 5,000 Mating Cycles |

| Normal Force | The contact is Pre-loaded Maximum Deflection is 1.4mm 40g min. → Neutral Position 100g max. → Mated Position |

Electrical | |

| Current Capacity | 2A |

| Contact Resistance | 30mΩ max. |

| Dielectric Stength | 1,000V AC (min.) |

Materical and Finish | |

| Insulator | PA46 Stanyl (UL 94V-0), Black |

| Contact | Copper Alloy, Au 0.3㎛ over Ni Plated |

Environmental | |

| Operating Temperature Range | -40℃ to +100℃ |

| Product withstanding Reflow Sodering | 260℃ for 10 Seconds |

|

|

|

|

|

|

|

|

|

Microphones must be hand soldered or socketed because the Mylar diaphragm inside the microphone would melt if it were reflow soldered directly to the circuit board. A socket eliminates the expense of hand soldering. |

|

Socket is designed for bottom entry, i.e., the microphone plugs through the circuit board into the socket on the opposite side. This feature achieves a low microphone profile suitable for "shirt pocket" sized phones. |

|

Sockets are supplied on 12mm wide tape (6,500 per 13"reel) to feed industry standard "pick and place" assembly machines. |

|

The assembly and soldering technique for this socket is called "intrusive reflow". Instrusive reflow (also called "pin-in paste")is a technique of using conventional thrue-hole components in a reflow soldering process. The solder paste will fill the PTH and achieve a solder joint as reliable as wave soldering. The volum of paste required to fill each hole can be increased by "overprinting" paste on the solder mask adjacent to the hole. |

|

The pimary benefit of the design is that the precision-machined receptacles have a large entry target, which permits automatic insertion of the microphone during final assembly of the telephone. |

.jpg)